Get pricing quote now and let our writing assistant provide the best assignment help. A good grade is all you need to boost up your academic excellence and we are all about it.

Our Location

- Galleria, Jalan Teknokrat 6, Cyber 5, 63000 Cyberjaya, Selangor. Malaysia

- km.assignment.services at gmail.com

- +60 383119394

- +60 19 2919412

Copyright © 2023. All rights reserved.

Table of Contents

Overview

Coca-Cola is the soft drink that is consumed the most frequently all over the world. It is available practically everywhere, and its brand name is familiar to speakers of most languages. TCCC produces and sells a wide variety of beverages, including Coca-Cola, Fanta, Sprite, water, juice, and even energy drinks. Whether it’s the drink itself or the company’s tried-and-true advertising efforts, Coca-Cola has become a household name because of the positive, energetic associations consumers have had with the brand. However, Coca-Cola has one of the largest and most efficiently run supply chains in the world. This is something that a person would overlook while describing the product that has achieved such phenomenal success (Singaram 2019).

Production system

The first stage of production process involve gathering ingredients like sugar, fruit juices, flavorings, and concentrates or beverage bases. Metal or aluminium cans, in addition to PET or glass bottles, will contain the final goods.

The treatment of water

The water used in production undergoes a number of specialised treatments before it is put to use. Treatments like these keep the water free of harmful bacteria and other microorganisms while also maintaining an optimal level of naturally occurring salts. This is carried out to fulfil particular needs in terms of composition and taste.

The concentrate

In designated tanks, sugar is dissolved in purified water before the mixture is filtered to remove any remaining impurities and produce syrup. It is not until this “simple syrup” is mixed with “concentration” or one of the many “basic preparations” that it can be called “final syrup” and used in the production of the many beverages. Flash pasteurization is a thermal process that helps to ensure that even the most delicate products retain their distinctive flavor and texture throughout their storage life.

Filling and packaging

To make a carbonated drink, carbon dioxide gas is added to water that has been filtered and refrigerated before being blended with the completed syrup. After that, modern automatic plants fill thousands of sterile containers, hermetically seal them, label them, code them, and put them through rigorous quality control tests every hour. Cans, PET bottles, and returnable glass bottles are all sold in convenient multi-packs, while non-returnable glass bottles are kept in boxes (Deighton 2011).

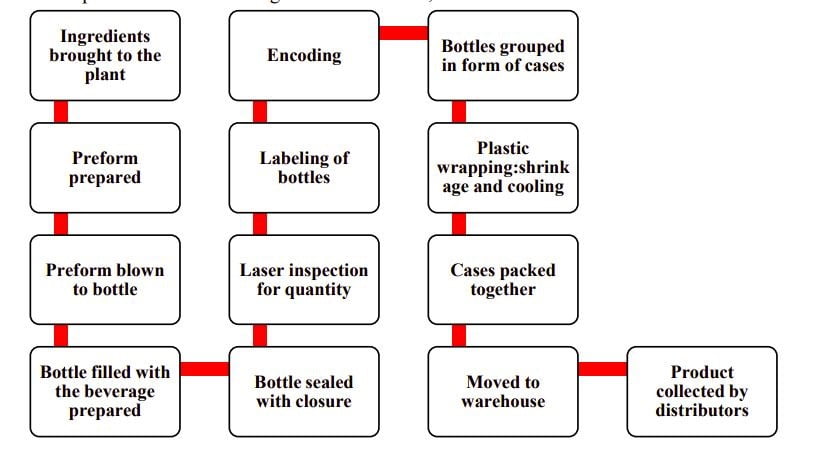

Flowchart

Layout

Getting that sought-after “fizziness,” is to completely saturate the franchised Coca-Cola manufacturing and distribution systems. The Coca-Cola Company simply makes the syrup concentrate, and then sells it to franchisees throughout the world who are in charge of bottling and delivering the soft drink to customers. The final product is made by bottlers who combine the syrup with filtered water, sugar, and other sweeteners to create a drink that is then carbonated and distributed to grocery shops, convenience stores, restaurants, and food service distributors. More than half of the volume sold worldwide is produced by entirely independent bottlers, despite The Coca-Cola Company owning a minority ownership in the franchises Coca-Cola Enterprises, Coca-Cola Amatil, Coca-Cola Hellenic Bottling Company, and Coca-Cola FEMSA.Local preferences for sweetness can be accommodated by independent bottlers (Banutu-Gomez 2012).

Coca-Cola uses rigorous quality control and inspection processes to guarantee that all of its carbonated soft drinks are up to par with global norms. In a nutshell, the processes consist of the following:

Step 1

Pure water undergoes rigorous filtration, softening, and disinfection processes using state-of-the-art technology to ensure that no impurities remain.

Step 2

Soft drinks begin with syrup, which is created by mixing sugar with the appropriate beverage concentration..

Step 3

The third stage involves saturating the mixture with carbon dioxide at low temperature and high pressure to achieve the desired “fizziness.”

Step 4

Machines measure out the ingredients and pour them into clean bottles at predetermined rates, while yet another machine cans, caps, or seal the containers.

Step 5

After being labeled and barcoded, the containers pass through an automated inspection system to make sure they are in compliance.

Step 6

Once the bottles and cans have passed their final quality control check, They are placed on wooden pallets after being processed by machines that pack them into cartons or boxes.

Step 7

The beverages are transported via trucks to distribution centers, where they are stored until they are shipped out to consumers.

Productivity

Coca-Cola manufacture method

After testing the source water to ensure it satisfies all of the criteria for being considered drinkable, a production site for bottles is chosen. An independent and accredited laboratory is responsible for carrying out these tests and analyses. The company also disclosed that it intends to make additional investments totaling $4 billion in China between the years 2012 and 2014. Hermetically sealed pipelines bring the water to the facilities, where it is stored in tanks within the secure water treatment areas of the facilities. The syrup used in the production of Coca-Cola drinking goods is derived from double-refined sugar, and the products also contain carbonated soda, filtered water, and concentrate. To make sugar syrup, purified water and double refined sugar are combined and stirred together. Following the addition of Coca-Cola concentrate to the sugar syrup, the mixture is next carbonated to provide the fizz (Tien 2020).

Packaging and sanitizing systems

First, the water that has been cleaned, filtered, and purified is used to wash and rinse the empty bottles that have been returned from the market. The plant is responsible for the production of Coca-Cola, Sprite, Fanta, and Minute Maid beverages, among others. After this, the bottles are immersed in a liquid that is heated to a very high temperature in order to eliminate any leftover dust particles. After that, a spray that is intended for intensive cleaning is used to sanitize them. The method in question is known as hydro wash. Technicians use electronic inspection and manual visual inspection to ensure that sanitised bottles are in good condition. The bottles that have been checked are then loaded onto the automatic conveyors so that they can be filled. Conveyors make it possible to precisely fill each bottle and automatically seal them, ensuring that the process is completely hygienic. A data number and details on the day, month, shift, and factory where the beverage was produced are labelled onto each bottle before they are packed in their appropriate cartons and shipped out onto the market (Ringold 1998).

The impact that Coca-Cola has had on the Chinese market

In the ten years that followed the end of the First World War, Coca-Cola established its first manufacturing facility in China. It does it through two joint ventures established in Hong Kong, namely Swire Beverages and Kerry Group, which provide it ownership holdings in the majority of its factories. As of September 2012, the corporation operated 42 production facilities across the globe. In 2010, Luohe’s plant was one of three in China, along with Sanshui in Guangdong province and Hohhot in Inner Mongolia. In March of 2012, a new bottling plant opened in the city of Yingkou in Liaoning Province. It has been said that the Coca-Cola bottling plant in Yingkou is the largest of its kind in all of China. China is the Coca-Cola Company’s third biggest market, after the United States and Mexico. Coca-Cola’s sales in China increased by 13% in 2011, and now make up 8% of the company’s total sales volume worldwide (S.B. 2020).

Production strategy

Coca Cola is known all over the world and is very popular because it has a unique way of marketing itself. The plan can be broken into the following parts:

Plan for a product

Coca-Cola has over 500 distinct products available. Its worldwide success in the soft drink industry may be attributed in large part to a well-planned product strategy that incorporates a marketing mix. Soft drinks such as Coca-Cola, Minute Maid, Diet Coke, Light, Coca-Cola Life, Coca-Cola Zero, Sprite, Fanta, and many more come in a broad range of sizes and tastes. They have a huge impact, and they bring in a lot of cash.

How to set prices

Coca-price Cola’s stayed the same at five cents for about 73 years. With more competition from companies like Pepsi, the company had to make changes to how it set prices. It doesn’t change its price by a lot, and it doesn’t raise it for no reason, because that would make people doubt the quality of the product and switch to something else.

Strategy in Place

Due to a large distribution network, Coca-Cola can be found just about anywhere. All of the Americas, all of Africa, all of Europe, all of the Pacific, and all of Asia are among the six regions we support. Products are manufactured, packaged, and delivered to sales representatives by the bottling partners. Next, the agents transport the stock to the distributors and retailers before finally reaching the end consumer. Coca-Cola also has a vast distribution system of retail outlets dedicated to the recycling of glass bottles. Money and other resources are thus conserved.

Plan for advertising

Coca-Cola employs a wide range of promotional tactics to keep up with the industry’s intense rivalry. Spending as much as $4 million annually on domestic and international advertising.

Classic font, logo, and bottle

Coca-Cola held a contest for people all over the world to design the bottle. The winner of the contest used the design of a cocoa pod, which the company then used to promote its shape and logo. It stands out from its competitors because its logo is written in Spencerian script. The way Coca-Cola markets itself with its logo makes sure that people will remember it.

Placement in a specific area

It was released in nearly fifty countries in 2018, and since then, “Share a Coke” has become a massive success. Promotional materials featuring local celebrities and other messages written in the culture of the intended audience.

Sponsorships

The company’s name recognition has increased thanks to its support of high-profile events such as American Idol, NASCAR, the Olympics, and more. Coca-Cola is one of the Olympic Games’ official sponsors and has been since 1928, supporting athletes, officials, and fans from all over the globe.

Social media

To keep up with the times, Coca-Cola has shifted its marketing efforts to focus primarily on online and social media platforms. It distributes visual content via social media marketing channels like Facebook, Twitter, Instagram, YouTube, and Snapchat. Search engine optimization (SEO), email marketing (EMA), content marketing (CM), and video marketing are at the core of Coca-Cola’s marketing strategy (Chu 2020).

Supply strategies

Other things that contribute to the supply chain of Coca-Cola include the following:

1. Innovation

Coca-Cola Enterprises is skilled at incorporating innovative systems into its supply chain. The company, for instance, produces the bottles and cans used to hold its beverages with the help of 3D printing technology.

2. Individuals

Coca-Cola’s team of logistics experts consists of over a hundred people who work together to guarantee that every bottle arrives safely from the factory to the consumer’s fridge.

3. Relationships with retail partners that are maintained over the long run

Coca-Cola has worked hard over the past few decades to earn a reputation as a reliable and respected vendor among its retail partners. The company’s growth alongside McDonald’s since 1955 is just one example.

4. A program for managing relationships with suppliers

Coca-vice Cola’s president of the US supply chain, Helen Davis, often hosts “supplier innovation days.” The company’s marketing and procurement departments use these occasions to highlight the organization’s product needs in the market, while the suppliers present the most recent innovations they have developed. In addition, the program’s major suppliers are invited to quarterly meetings where their progress is discussed and evaluated.

5. Strict adherence to quality standards

Coca-Cola is very particular about the quality of its products and the procedures that produce them. Example: Coca-Cola HBC, a bottling franchise partner of Coca-Cola Enterprises, insists that all of its suppliers be in possession of appropriate quality, environmental, and health safety certifications.

6. Council for the Global Supply Chain

The Global Supply Chain Council was established by the multinational beverage company to establish and oversee subcommittees whose primary responsibility is to implement the company’s supply chain strategy. Through the Council’s central hub, employees and other supply chain participants can pool their knowledge and offer suggestions for improvement.

7. Working in close proximity with the bottlers

Manufacturers and Coca-Cola distributors are all required to abide by the same set of rules. Due to this, most strategic choices are taken at a high level of management. Since the bottling partners’ headquarters are in charge of most operations, the bottling partners’ regional offices are responsible for serving their respective regions. Both the regional office and the bottler’s office report to The Coca-Cola Export Corporation. They handle everything related to distribution as a team (TCCEC). The bottling company’s headquarters links the manufacturing plant with regional distribution centres and retail outlets around the globe, creating an integrated supply chain (Demetris 2003).

Works Cited

Banutu-Gomez, Michael Ba. “COCA-COLA: International Business Strategy for Globalization.” Accelerating the world’s research., 2012.

Chu, Bodi. “Analysis on the Success of Coca-Cola Marketing Strategy.” Advances in Economics, Business and Management Research, 2020.

Deighton, John. “Coca-Cola on Facebook.” Harvard Business School Marketing Unit Case No. 511-110, 2011.

Demetris. “The Strategic Positioning of Coca-Cola in their Global Marketing Operation.” The Marketing Review, 2003.

Johnson, Victoria. “Crisis management in Belgium: the case of Coca‐Cola.” Corporate Communications: An International Journal, 2003.

Ringold, Debra Jones. “Consumer Response to Product Withdrawal: The Reformulation of Coca-Cola: ABSTRACT.” Psychology & Marketing, 1998.

S.B., Erkinov. “CULTURE AND ITS INFLUENCE ON CONSUMER BEHAVIOR IN THE CONTEXT OF MARKETING (in case of “Coca-Cola” company).” CULTURE AND ITS INFLUENCE ON CONSUMER BEHAVIOR IN THE CONTEXT OF MARKETING, 2020.

Singaram, Rukmani. “Coca Cola: A study on the marketing strategies for millenniums focusing on India.” International Journal of Advanced Research and Development, 2019.

Tien, Nguyen Hoang. “The role of brand and brand management in creating business value case of Coca-cola Vietnam.” 2020.